Ball Mill RETSCH powerful grinding and .

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

WhatsApp)

WhatsApp)

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in ... Lab Rapid Ball Mill; Lab Glove Box / Operation .

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

Operation Principle of Iron Ore Ball Mill Xinhai. The grinding operation of Iron ore ball mill has been very mature and its stable performance is why it has ...

Ball mill operation and maintenance. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball ...

Ceramic ball mill . Cylinder speed:1436r/min Weight: Motor power: Ceramic ball mill is mainly used for mixing, grinding process. It can be used both ...

PDF Mazak 640 Operation . mazak cnc programming manual mill PDF mazak coolant pump manual PDF u operation and maintenance manual PDF theory of operation .

DOVE is a manufacturer for ball Mills, grinders, crushers, grinding crushing equipment for gold mining, gemstone mining, metal mining, mineral mining

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and .

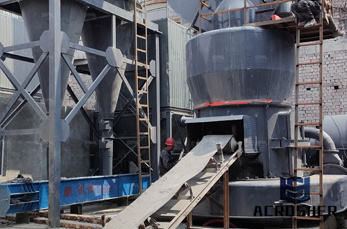

operation of cement ball mill. operation of, pew series is born with innovative significance. It is newly designed and improved by our experts on basis of their ...

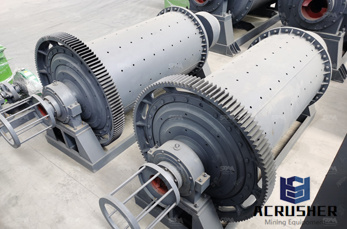

The machine running is smooth operation and reliable . Ball mill host, including cylinder body,which lined with wearresistant lining material, a load cylinder maintain ...

· Pulverizing the coal to a fine powder is often a critical function within the operation from the power plant. ... * This referred to as Tube mill or Ball mill These .

Highlights • Effect of operating variables on the energy efficiency of ball mill analyzed. • Rates of particle breakage and production of fines per unit power ...

Ball mills account for the majority of all mills in cement plants and therefore the optimization of ... Optimizing the operation of the cement mill Publications.

Easy Operating Ball Mill, Wholesale Various High Quality Easy Operating Ball Mill Products from Global Easy Operating Ball Mill Suppliers and Easy Operating Ball Mill ...

Ball mill should keep even feeding in operation; the even feeding means stable feeding quantity and same particle size distribution.

· RecrystallizedRocket. Loading ... Working principle of Ball Mill /ball cement milling machinery plant Group Duration: 3:46.

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

The Ball Mill operation and maintenance seminar will offer the participants the ability to be trained on the mill technology and components, best practices for ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, new ...

Ball mill installation and operation observationJiangsu . Ball mill installation and operation observation. Ball mill installation quality is the key to ensure ...

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that ...

WhatsApp)

WhatsApp)