Grinding in Ball Mills: Modeling and Process Control

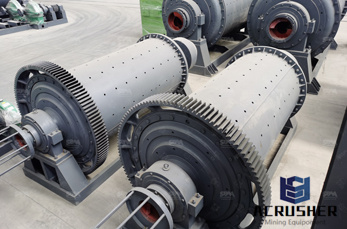

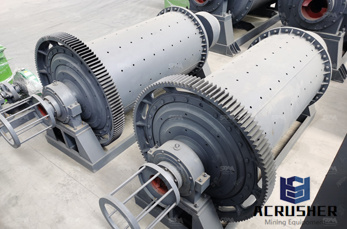

Grinding in Ball Mills: Modeling and Process Control ... The mill is driven by a girth gear bolted to ... The design of a ball mill can vary significantly ...

WhatsApp)

WhatsApp)

Grinding in Ball Mills: Modeling and Process Control ... The mill is driven by a girth gear bolted to ... The design of a ball mill can vary significantly ...

Previous Post Next Post Contents1 advanced comprehensive guide for ball mill design, operation maintenance Mr Ortega2 1 FEED AND FEED ...

henan bailing can provide ball mill technology,ball mill operation,ball mill technology,ball mill price,ball mill What is the technique structure of ball mill .

Nov 12, 2014· Video embedded· 3D Animation Demo working site of Ball Mill ... Ltd. ball mill is widely used ... Overflow Discharge Ball Mill in Operation .

Ball Mill Maintenance Manual The purpose of ... involved in the actual installation and operation of the mill ... Ball Mill Maintenance Installation Procedure.

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the ...

Ball Mill is a milling machine that consists of a hallow cylinder containing balls... The large balls tend to break down the coarse feed mater...Used for...

CHANGSHA TIANCHUANG POWDER TECHNOLOGY CO., LTD. is one of largest professional manufacturers in China engaging in design, manufacture, and sales of .

operation jaw ball mill sale,mode of operation of a hammer mill,operation fine iron grinders,operation of a conveyor belt,operation jaw ball mill sale

Variety of Applications. DOVE ® offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material ...

Operation Of The Ball Mill,1 Oct 2013 Mechanochemistry, a subfield of physical chemistry, deals with the impact of mechanical energy on solids and the ensuing .

Product Information Planetary Ball Mill PM 100 medicine / pharmaceuticals Feed material soft, hard, brittle, fibrous dry or wet Size reduction principle impact ...

A ball mill grinds ores and other materials to a typical product size of 35 mesh or finer. ... Operation Ball mills operate either in open or closed circuit.

Ball and socket bearings can be furnished if ... The following cost advantages should be considered when evaluating rod mill grinding: Rod Mills use low cost grinding ...

used milling machine checklist,high energy ball milling method,milling operation armenia for sale,bean pulp powder grinding machine milling equipment,milling ...

Operating Manual For Planetary Mixers . 2 ... The planetary mixer/mill is capable of emulating ball mills of conventional design, simulating the types of

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball ... Optimizing the operation of the cement mill.

Ball mill operation is often regarded as something of a mystery for several reasons. Ball milling is not an art it''s just physics. The first problem will ball ...

Across International is a leading supplier of laboratory ball mills including planetary ball mills, high energy ball mills, all directional ball mills and ball mill ...

Particle size reduction of materials in a ball mill with the ... One piece ceramic cover with silicone O Ring allows for leakproof operation. ... Steel Ball Mills.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Planetary Mills for fine grinding of various materials, ... Planetary Ball Mills ... Automatic check of the locks of the bowls in the mill ;

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotat...

A cement mill (or finish mill in ... The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, ...

WhatsApp)

WhatsApp)